Tempo R 12-18

12-18

450-800mm

>250hp

70litre

Robust capacity

Tempo R 12-18 is a rigid, mounted high-speed planter available with 12 or 18 row units, and fertiliser metering as an option. With easily adjustable row spacing, it is possible to plant numerous crops with the same machine, enabling greater usage. The three-point linkage provides excellent manoeuvrability and short headlands, Additionally, a rigid frame benefits from fewer moving parts, minimal weight and reduced maintenance without compromising the excellent precision Tempo R offers.

Väderstad Tempo is a new generation high-speed planter, delivering an unmatched precision at double the speed of traditional planters. No-till, min-till or conventional tillage – Tempo performs exceptionally in all conditions. The crops gets the best start possible which results in an even emergence.

Selected features

Multiple crops with one machine

Tempo R has a frame designed to enable simple setup of row spacing and number of row units, including odd numbers.

The row spacing on the 18 row Tempo R 18 can be set down to 450mm, while the 12-row model can be configured between 700 to 800mm. This results in more hectares per season and consequently lowers costs.

Transport wheels for wider models

Equipped with optional transport wheels and drawbar, Tempo R 12 and Tempo R 18 can be easily transported between the fields on the farm.

Despite the wide working width, the transport width fits under 3 metres.

FH 2200 - High capacity fertiliser metering

The front mounted fertiliser hopper FH 2200 enables high precision combi-drilling. The 2200 litre hopper is equipped with the electric Fenix III metering system, suitable for high capacity and high working speeds in the field.

FH 2200 integrates with the iPad-based control system Väderstad E-Control or the ISOBUS-terminal of the tractor.

Full control at your fingertips

The iPad-based control system, Väderstad E-Control wirelessly delivers data about each seed that travels through the machine, including seeding quality, skips, doubles, distance in the row, and rate.

You benefit from user-friendly remote set up and calibration, as well as easy, real-time monitoring and control.

With the iPad you can upload the most recent program software which allows you to benefit from future developments.

QuickStart

See our QuickStart guides for your Tempo R.

Product concept

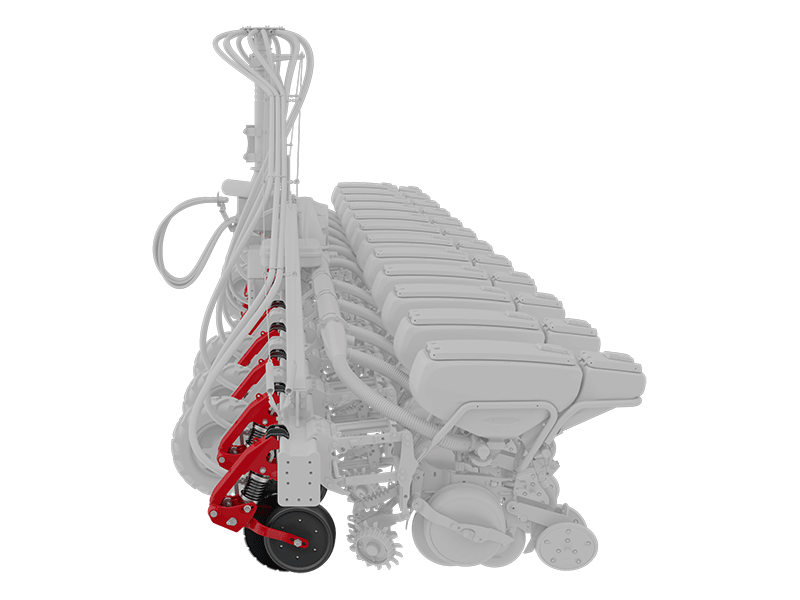

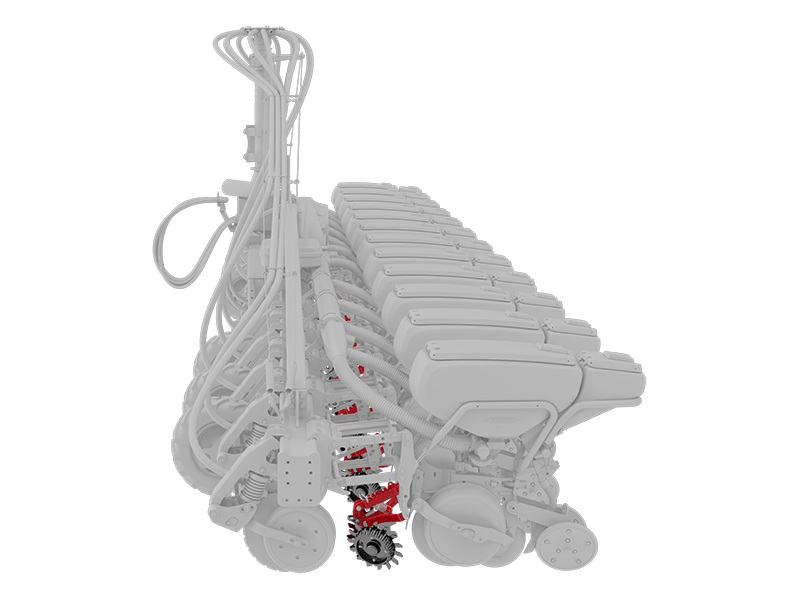

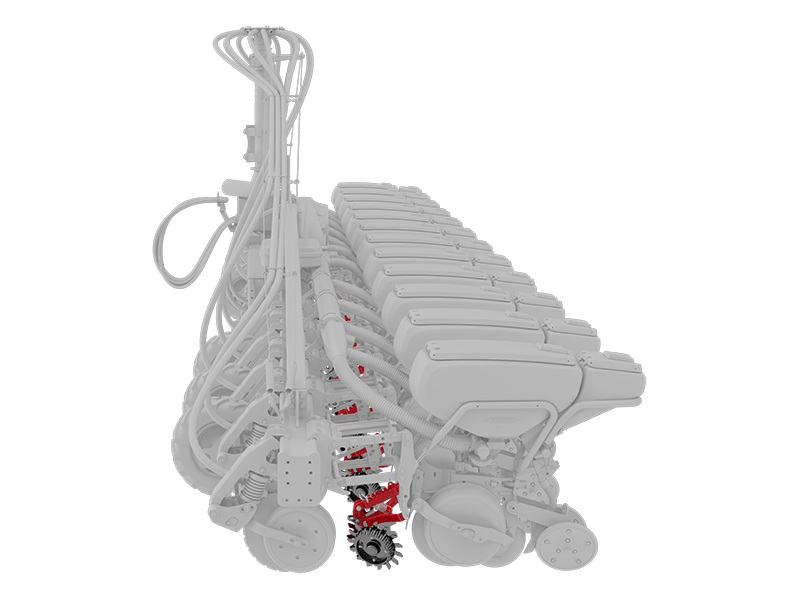

Zone 1 - Fertiliser placement

In combination with the front hopper FH 2200, Tempo is able to combi-drill fertiliser at high speed. The high capacity fertiliser coulters maintains the high precision even at high speed.

2

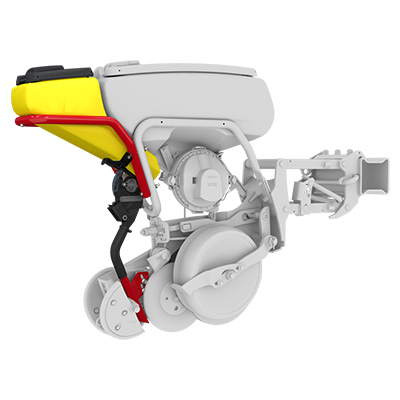

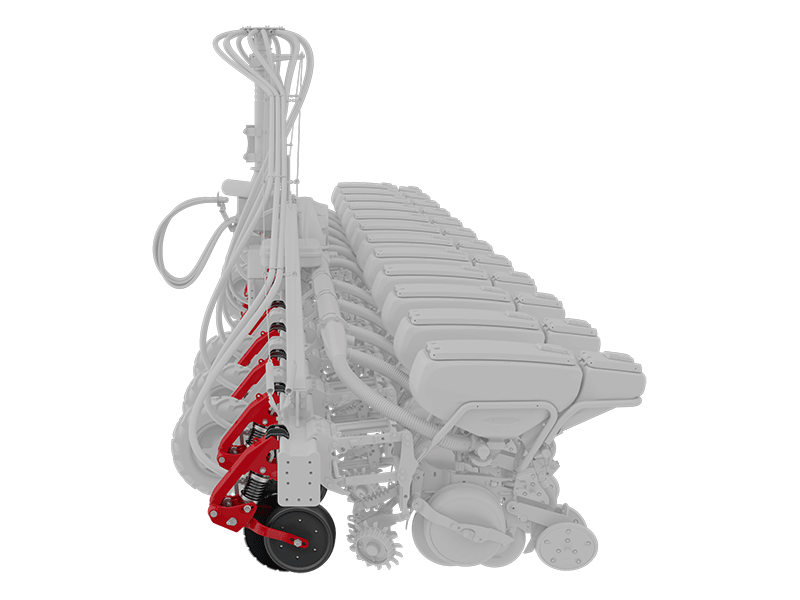

Zone 3 - Seed placement

With Tempo, planting can be carried out at very high speed, without compromising exceptional precision and accuracy. Tempo is extremely accurate and the seed meter assures perfect placement for every seed. This precision is of greatest importance to maximise the yield.

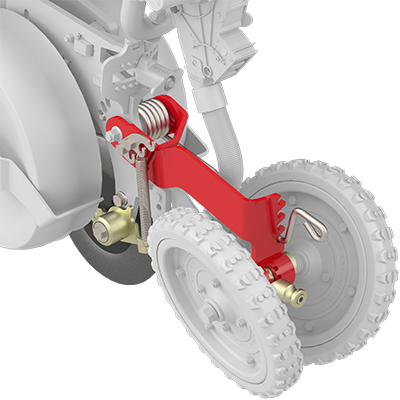

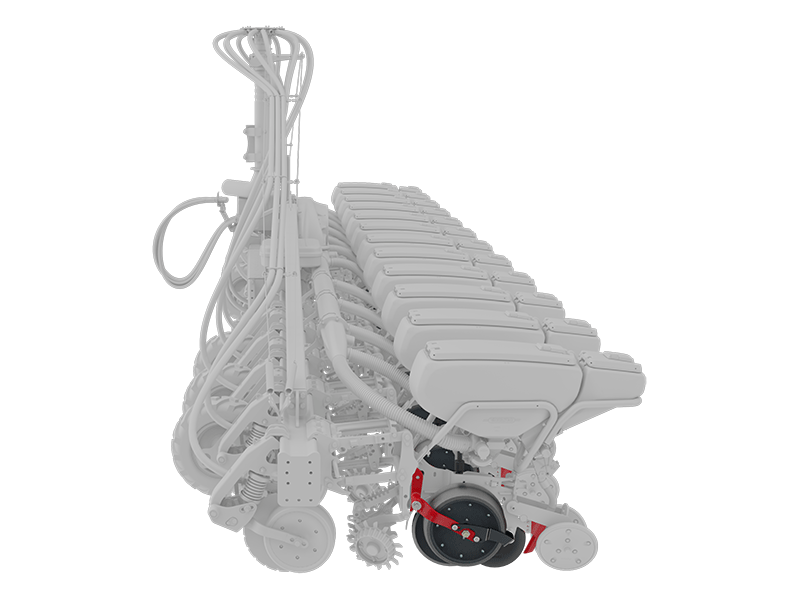

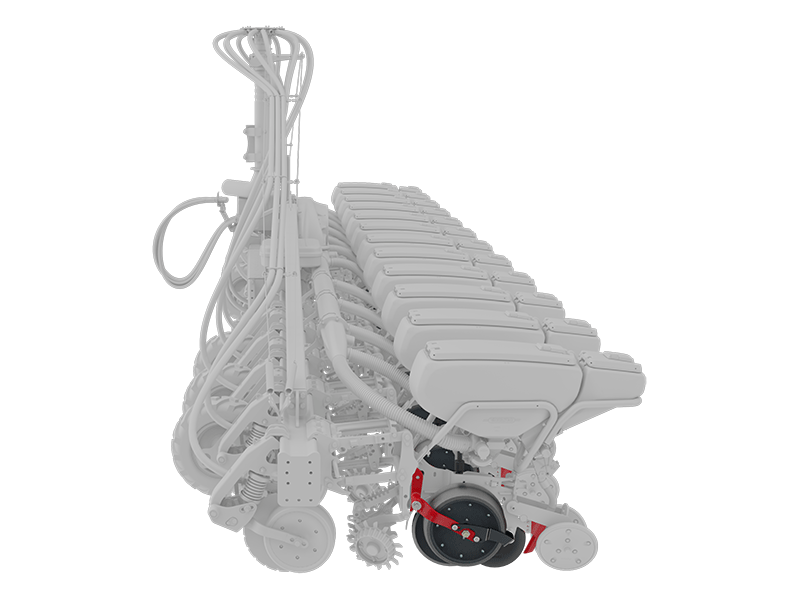

Zone 4 - Closing

When the seed is planted the closing wheel shut the seed slot and ensures perfect conditions for germination. Depending on farming requirements, the interface further allows for several industry-standard third-party closing wheel solutions.

Image gallery

Technical data

| Tempo R | 12 | 18 |

| Number of rows | 12 | 18 |

| Row spacing (mm) | 700/750/762/800 | 450/457/500/508 |

| Working width (m) | 8,4-9,6 | 8,55-9,65 |

| Transport width (m) | 3,0 (with transport wheel) | 3,0 (with transport wheel) |

| Transport height (m) | 2,15 | 2,15 |

| Volume seed hopper per row unit (l) | 70 | 70 |

| Volume micro granulate hopper per row unit (l) | 17 | 17 |

| Weight without combi (kg) | 2800-4200 | 3400-4600 |

| Weight with combi (kg) | - | - |

| Coulter pressure max (kg) | 325 | 325 |

| Recommended working speed (km/h) | 10-17 | 10-17 |

| Hydraulic capacity (l/min) | 40 | 40 |

| Hydraulic requirements | 1-2+FR | 1-2+FR |

| Draught requirements from (hp) | 250 | 300 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic | N/A = Not available |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.