Proceed V 24

24

225/250 mm

>300 hp

2200 litre

Exact precision for each seed

Proceed V 24 is a precision seed drill, available with 24 rows and a working width of 6 metres. It operates with either 225 mm or 250 mm row spacing and has a 2,200-litre seed hopper. To enable fertiliser distribution, Proceed V 24 can be combined with the front hopper FH 2200.

One machine. Many possibilities.

The precision seed drill Proceed V can place even the smallest seed at the perfect depth with millimetre precision. The result is a significant improvement in yield potential, while drastically lowering the seed rate.

Stronger crops

The strong and even crop development leads to higher output per seed. This is key to maintaining or even increasing the yield level while drastically lowering the seed rate.

Lower seed rates

The seed singulation and precision allow for drastically lower seed rates.

Even crops

The benefits of a strong and even plant population are numerous. The ability to optimise treatments throughout the crop year is one of them.

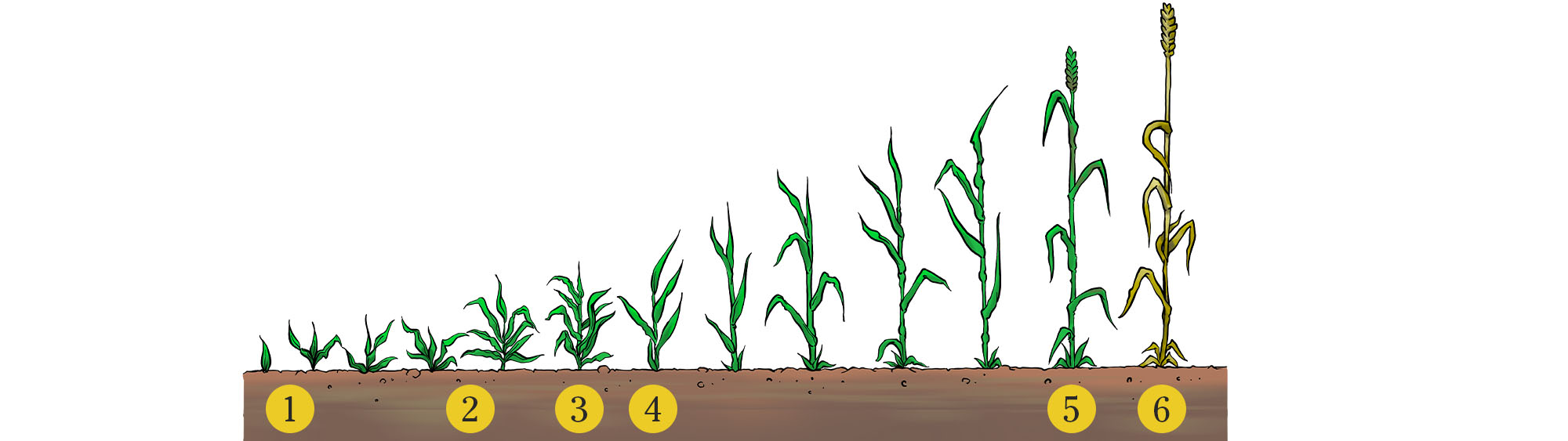

Strong crop development: Proceed vs Traditional

More biomass, more shoots per plant, straighter rows, and even heights.

Ten weeks after seeding, we already see the rewards of perfect precision at the perfect depth.

Ten weeks after seeding, field trials of winter wheat at a seed rate of 150 seeds/m² show a 102% increase in plant biomass, a 72% increase in root biomass, and 62% more shoots per plant compared to a modern seed drill.

A new category of seed establishment

Previously, there has been a clear distinction between grain seed drills and precision planters for row crops. Proceed changes this. By merging both technologies into one, it brings the precision of planters to grain crops, while also maintaining the ability to plant at wider row distances. This results in unprecedented crop quality paired with great versatility in farming practices. Proceed sets a new standard in crop establishment.

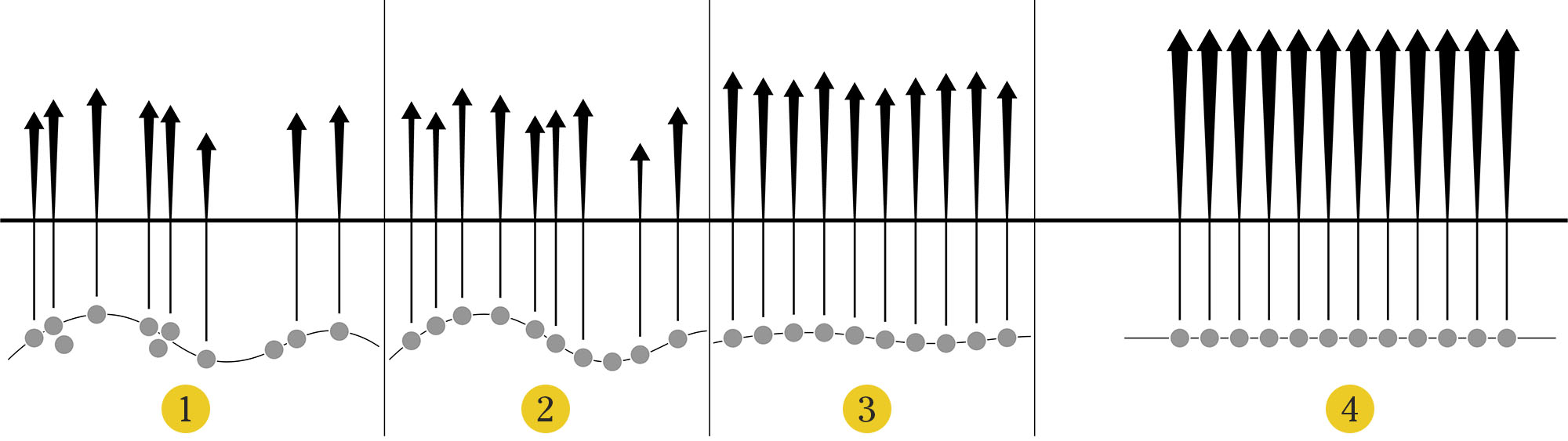

Comparison in crop emergence and seed placement

- Traditional seed drill

- Seed drill with singulation

- Conventional planter

- Väderstad Proceed

Improved yield with millimetre precision

Proceed can place even the smallest seed at the perfect depth with millimetre precision. The result is a significant improvement in yield potential, while drastically lowering the seed rate.

The first to optimise yield potential in cereals

Proceed delivers exact depth precision, singulated in-row precision, and perfect distribution across the working width. To ensure each seed has the same conditions, the row units act individually to optimise the seedbed and growth conditions for each seed. To maximise precision, Proceed is equipped with row-by-row shut-off and control.

“I am very impressed by the very homogeneous fields I see here, as a result of the accurate depth placement. I believe this will make the crop protection easy over the coming vegetation period.”

-Farmer hosting field trial

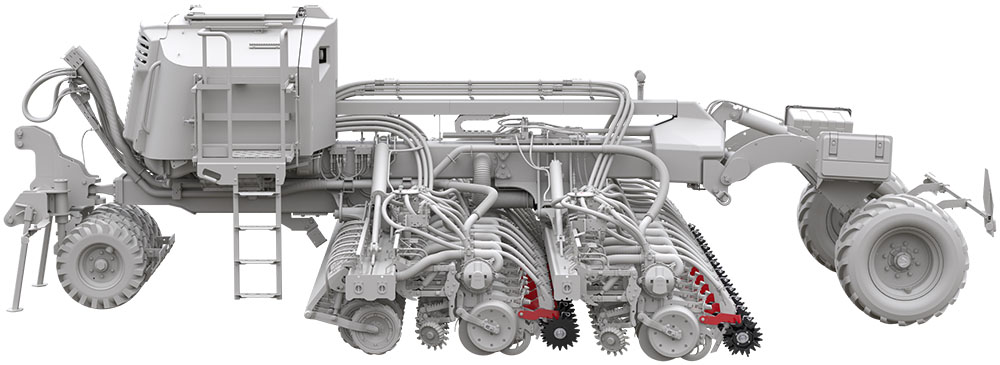

The Proceed row unit

The improvements in precision offered by Proceed, compared to a standard seed drill, can largely be attributed to the accuracy of its row units.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

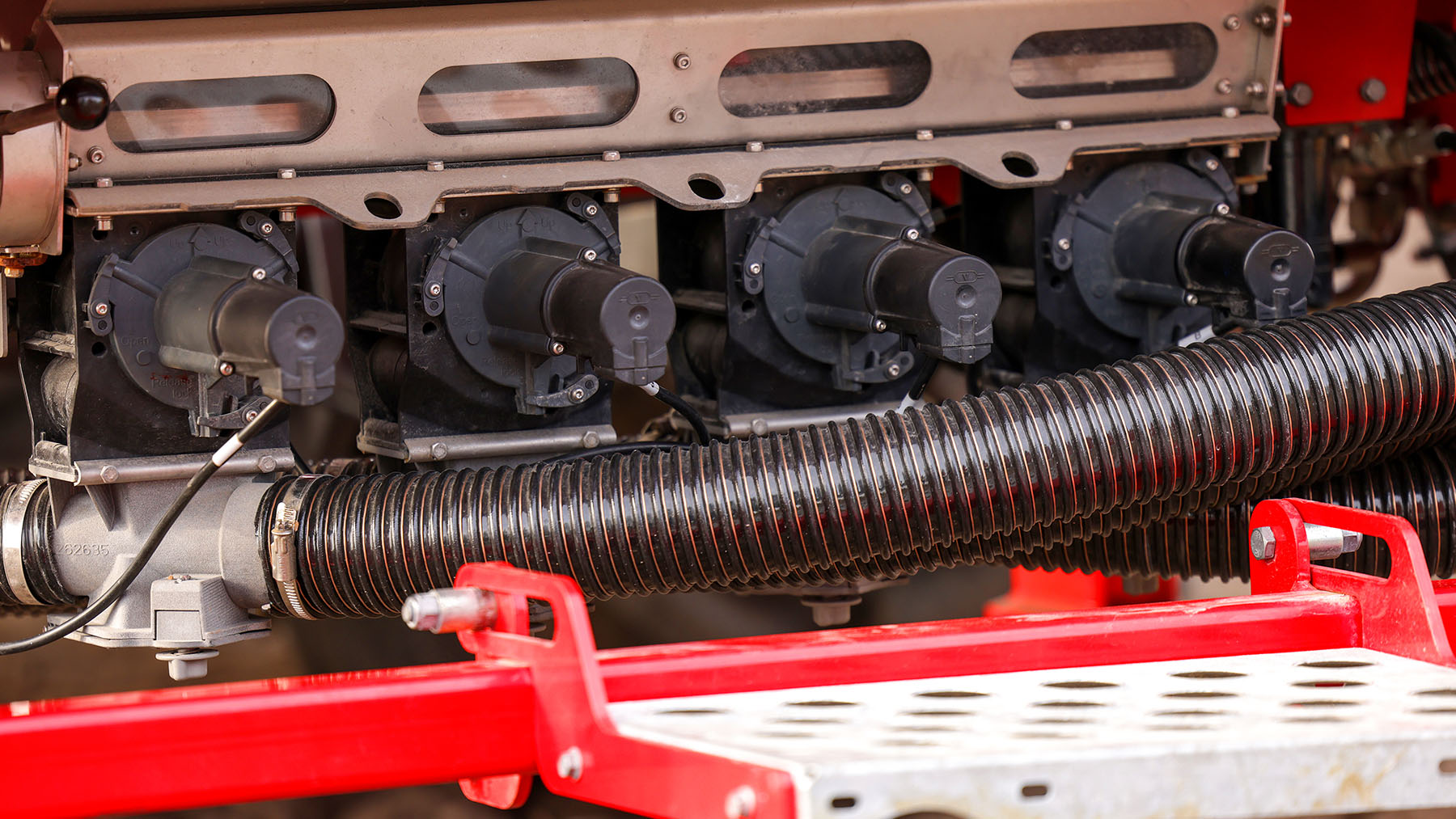

Precision seeding through positive air pressure

The Proceed seed meter uses positive air pressure to ensure each individual seed finds its place on the rotating seed discs, one by one. To guarantee top performance, three speed-independent singulators at the top of the seed meter remove any excess seeds.

When the seed reaches the seed tube, the air pressure is cut off, allowing the seed to be accurately placed into the seed tube. The air pressure then resumes control and shoots the seed down to the soil. Since all seeds experience the exact same transport time from the seed meter to the seed furrow, precision is ensured. At Väderstad, we call this PowerShoot technology.

A machine walkaround with Proceed V 24

Highest precision in all dimensions

Every component of Proceed is built to ensure the exact same start for all seeds. The even seed placement results in a crop that matures at an even rate and is more likely to reach its full yield potential.

Row-by-row pre-consolidation

Even if field conditions are potentially uneven in front of Proceed, the pre-consolidation wheels ensure uniform conditions for each individual row unit.

Perfectly even crop stand

Proceed delivers a perfectly even crop stand, which is key to reaching full yield potential. Most inputs and actions during the crop year are targeted at specific development stages to ensure maximum efficiency. An even population can be fertilised at the right time, receive crop protection or fungicide at the optimal development stage, and be harvested at peak maturity.

One year of full-scale field trials across Europe

Automatic levelling for excellent results

The Proceed V 24 detects its angle in two directions and automatically adjusts to maintain precise operation. For lateral adjustment, crucial in hilly conditions, the machine monitors the position of the parallel linkages of the outer row units and adjusts downforce to ensure even results.

In the driving direction, it actively senses the angle between its two sets of row units. If there’s a deviation, it adjusts the downforce on the pre-consolidation wheels to keep all row units parallel to the ground.

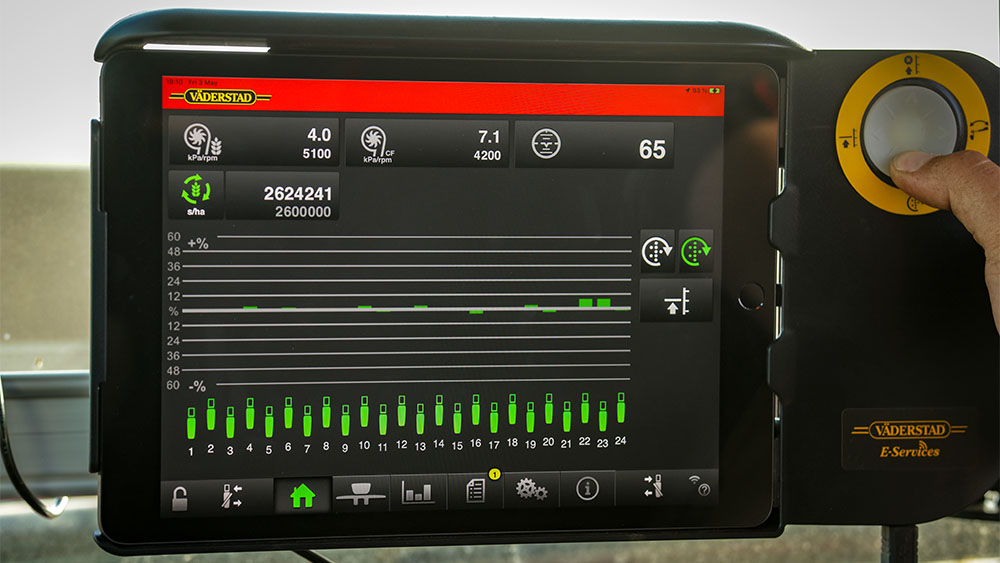

E-Control – The new generation control system

The iPad-based Väderstad E-Control system wirelessly connects to the Väderstad machine, enabling full access to its functions and data. You benefit from user-friendly remote setup and calibration, as well as real-time monitoring and control. E-Control is a fully portable control system, ready to be used whenever and wherever required. When calibrating the Väderstad machine, you can take the portable iPad out of the tractor and control the calibration from outside.

Precise fertiliser placement – Two alternatives

When combined with the front hopper FH 2200, which features four metering units, the Proceed V 24 can distribute fertiliser either in each seed row or between the seed rows at 450 mm or 500 mm spacing.

The in-row option enables starter fertiliser to be placed together with the seed for early access, thereby boosting the germination process. The side-band option allows the fertiliser to be placed 5 cm to the side of the seeds distributed from the first axle of row units, making it suitable for crops planted at 450 mm or 500 mm row spacing.

In-row fertiliser placement is available for all row spacing options.

Fertiliser placement 5cm to the side of the seeds is available for 450mm and 500mm row spacing.

Learn more about Proceed

Product concept

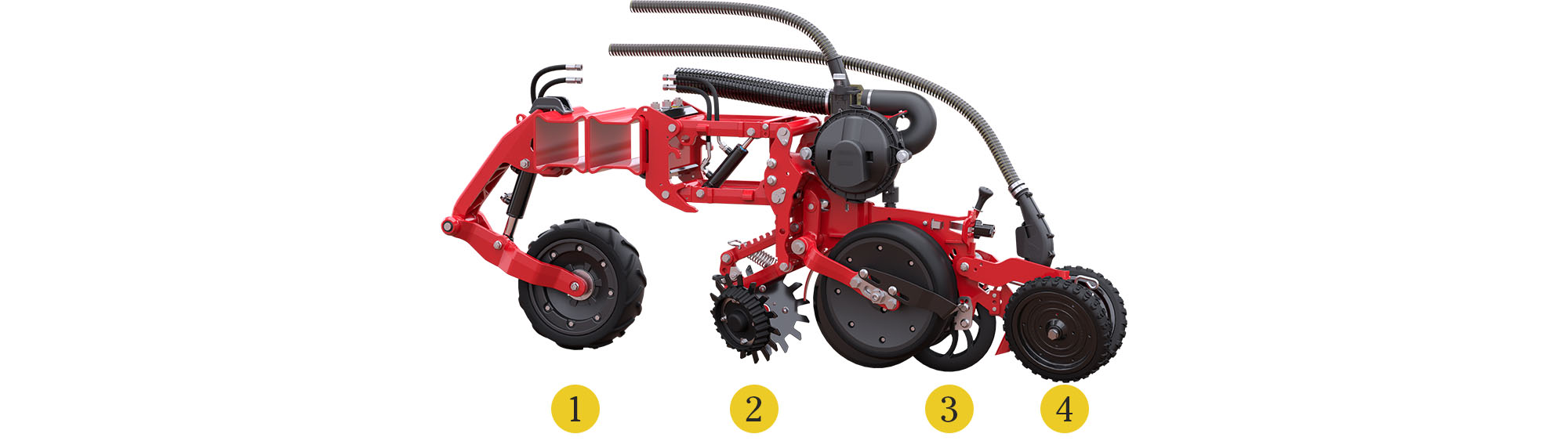

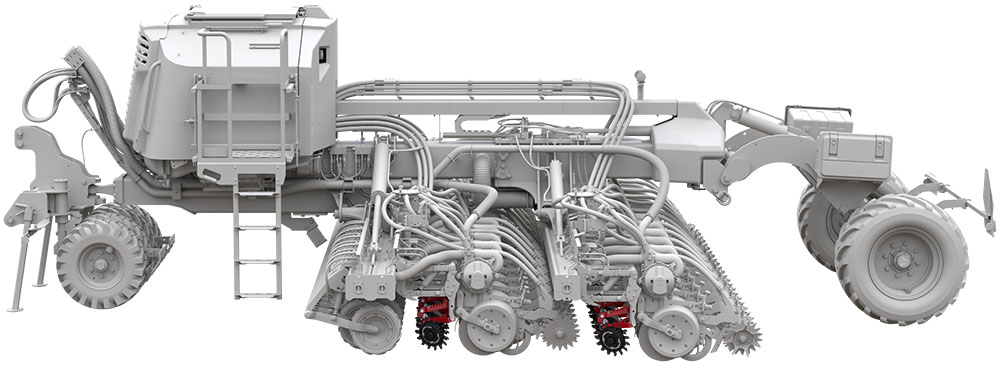

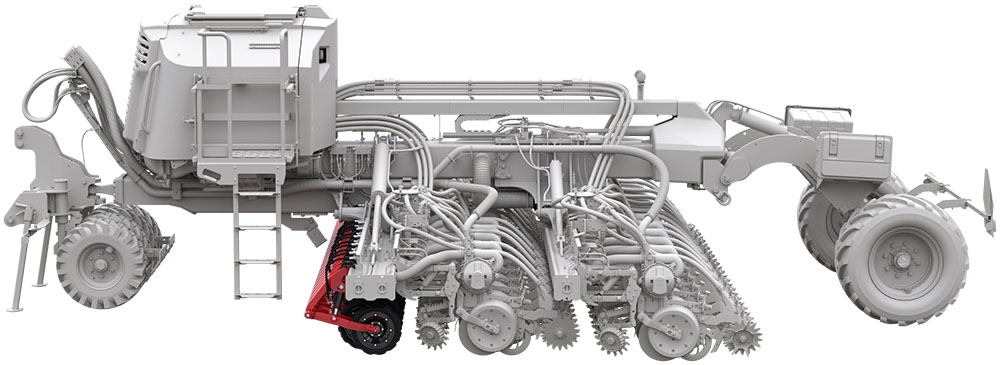

Zone 1 – Pre-consolidation

In front of each row unit, there is a pre-consolidation wheel. The pre-consolidation wheels eliminate irregularities and ensure even consolidation for each individual row unit. This ensures that each seed is placed under the same conditions, guaranteeing even seed depth, optimal moisture access, and uniform emergence.

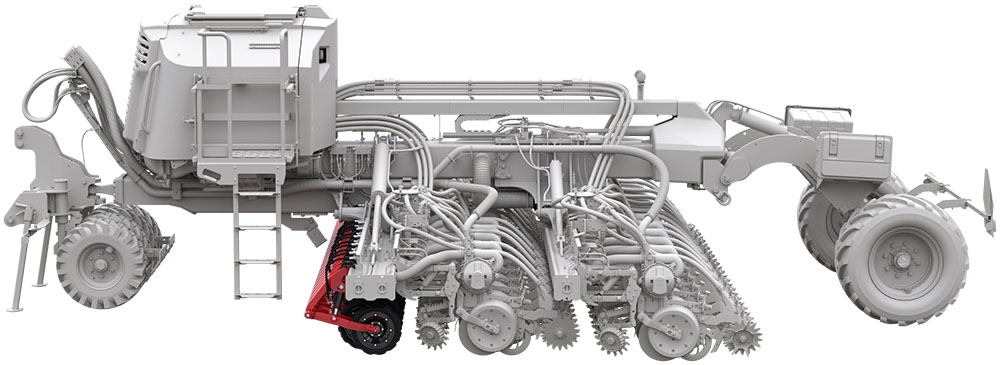

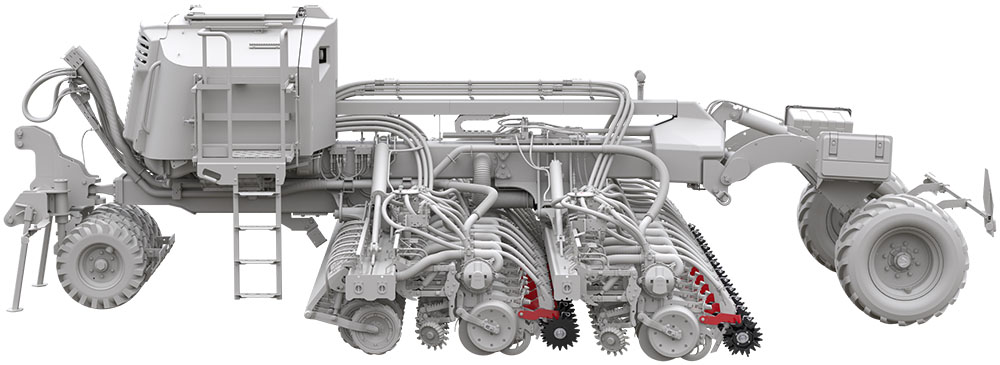

Zone 2 – Row cleaning (optional)

Row cleaners are an optional feature on Proceed. Their task is to remove crop residues, clods, and stones. The demand for row cleaners is significantly higher when operating in no-till conditions or in fields with a large amount of residue.

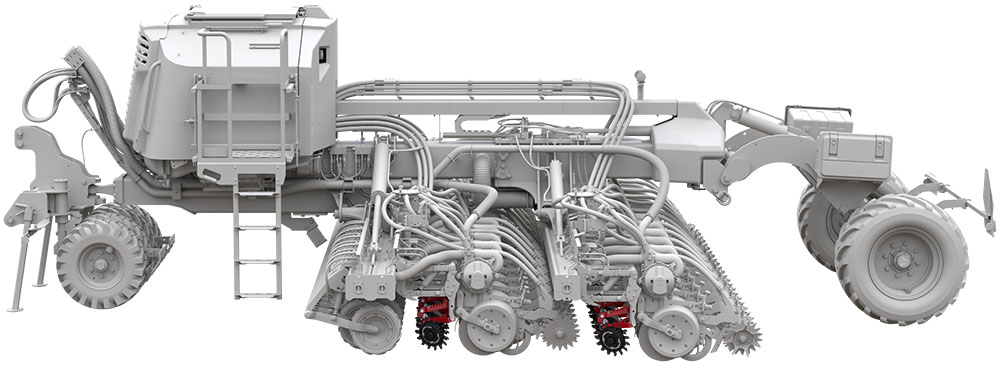

Zone 3 – Seed placement

Thanks to PowerShoot technology, the Proceed seed meter ensures precise placement of each seed. This level of accuracy is crucial for maximising yield.

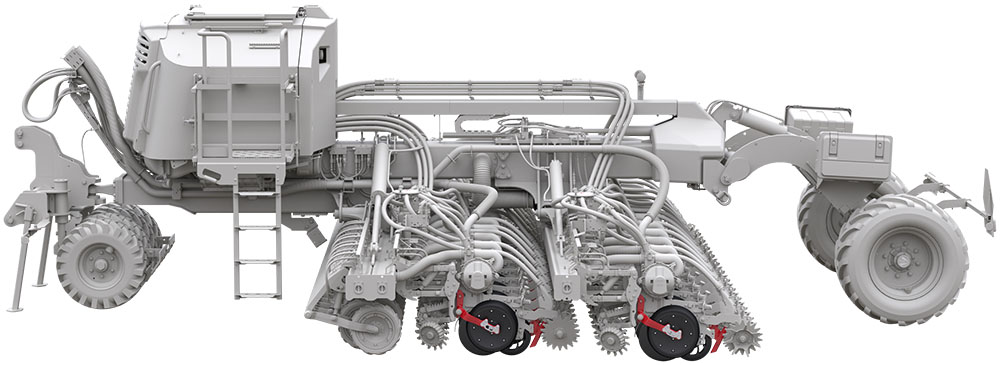

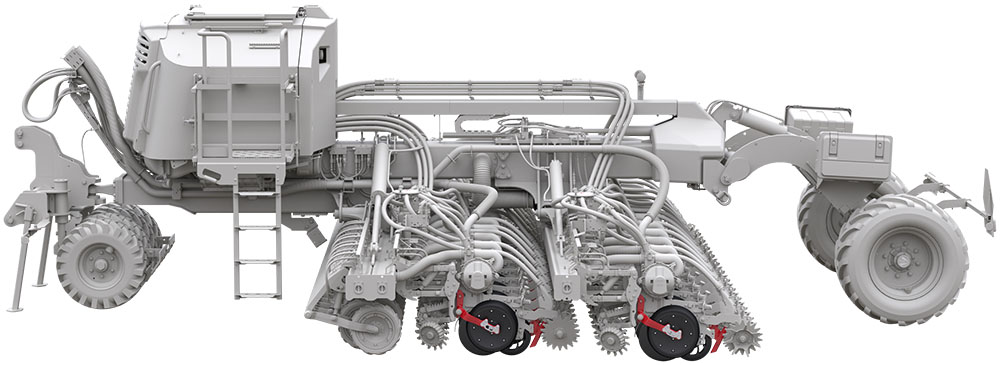

Zone 4 – Closing

When the seed is planted, the closing wheel closes the seed slot and ensures optimal conditions for germination. Depending on farming requirements, the interface also allows for several industry-standard third-party closing wheel solutions.

Image gallery

Technical data

| Proceed V 24 | |

| Number of rows | 24 |

| Row spacing (mm) | 225/250 |

| Frame width (m) | 6.1 |

| Working width (m) | 5.4-6.0 |

| Transport width (m) | 3.0 |

| Transport height (m) | 3.8 |

| Hopper volume (l) | 2200 |

| Filling height (m) | 2.6 |

| Weight (kg) | 10000-10260 |

| Coupling load (kg) | 6000 |

| Row unit downforce | Hydraulic with adaptive levelling system |

| Hydraulic requirement | 3 DA + FR + CD + P + LS |

| Oil flow requirement (l/min) | 130 |

| Draught requirement (hp) | 300 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| CD = Case drain | LS = Load sensing | DA = Double acting |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.