Tempo K 24

24

30"

>350hp

150 bu

Superior field productivity

The Tempo K is a high-capacity, high-speed planter for large scale farming operations. It is available with 24 row units, at 30 inch spacing. Tempo K stands out in the market thanks to its ability to deliver outstanding planting precision at 10-12 mph.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

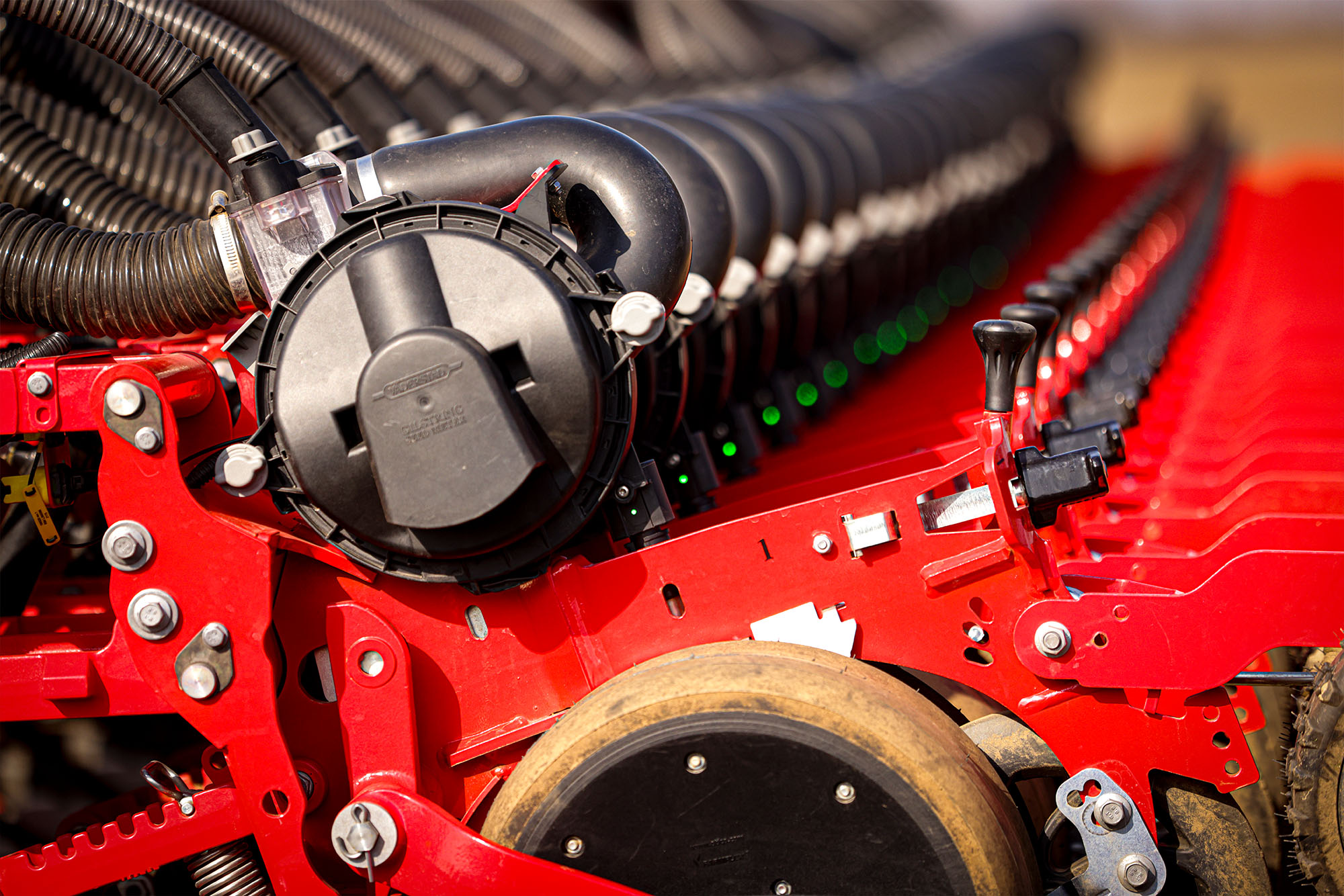

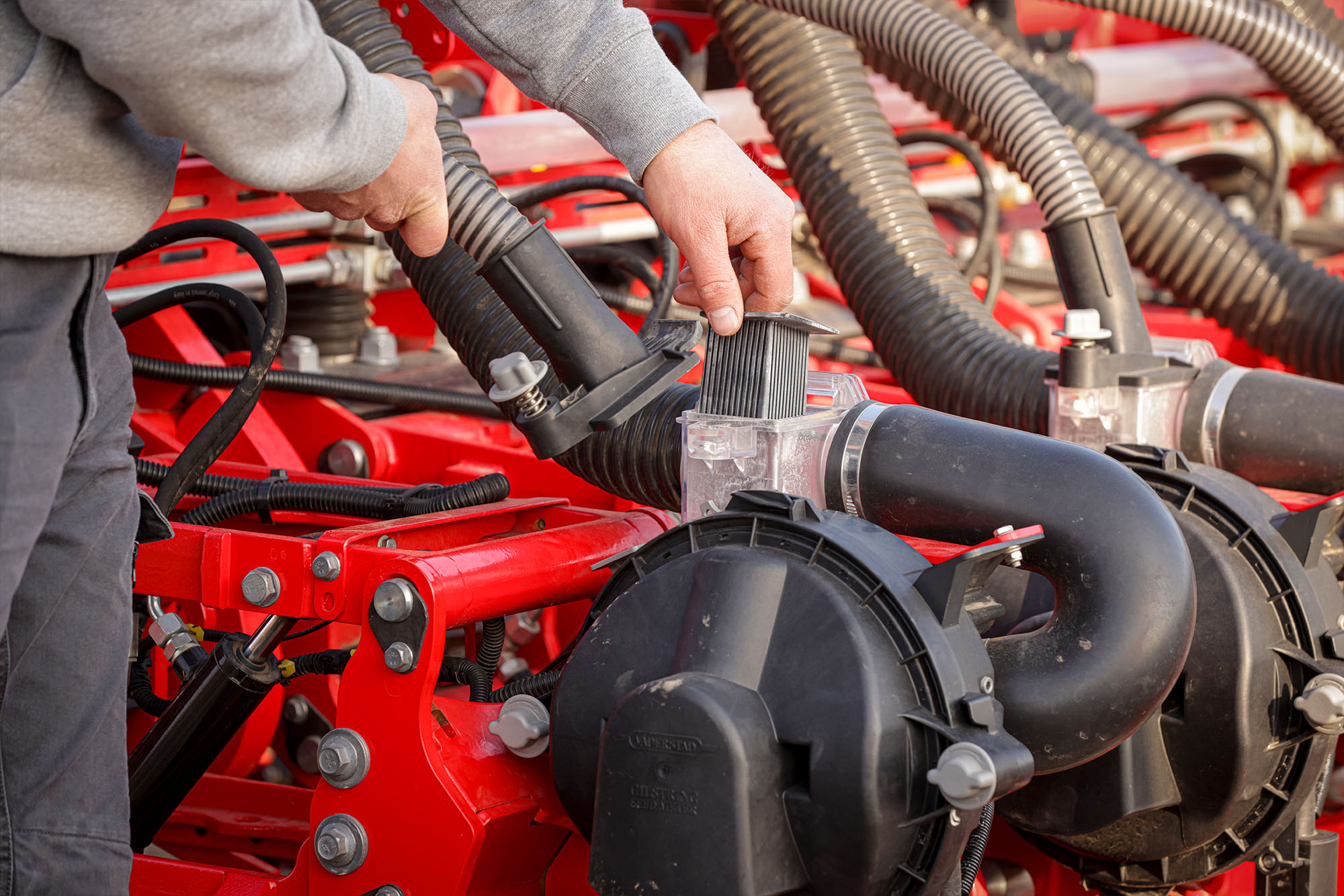

High capacity central fill system

Tempo K 24 is equipped with a 150-bushel seed capacity. The central fill system works as a pressurized system, constantly feeding the high-precision Tempo seed meters at the row units. When seeds have been delivered to the meters, the patented PowerShoot technology ensures excellent high-speed planting precision.

Liquid-ready

Tempo K is available with a 1,500-gallon liquid capacity as an option, divided into two 750-gallon on-board liquid tanks. This allows for the placement of two different fertilizers at planting.

Low compaction tracks

The Tempo K track system provides a large footprint utilizing flotation to reduce compaction. This maximizes the yield potential and the evenness of the crop population.

Perfect depth control

The Tempo K is equipped with hydraulic wing pressure, which transfers weight from the inner section of the planter to the outer wings. This allows the Tempo K to respond to any irregularities in the field and ensures even emergence.

Narrow transport

Narrow transport width is achieved through a front-folding design, as well as a telescoping hitch that extends during transport and locks in field position.

Optimized accuracy with next-level automation

By upgrading the data processing capabilities of the planter, additional features to ensure accuracy in the field are unlocked. The optional features are curve compensation, active hydraulic downforce and auto singulation.

Curve compensation ensures a consistent rate

Active sensors communicate when the machine is turning and adjust the metering output of each row unit to always ensure a consistent rate over the full Tempo planter width.

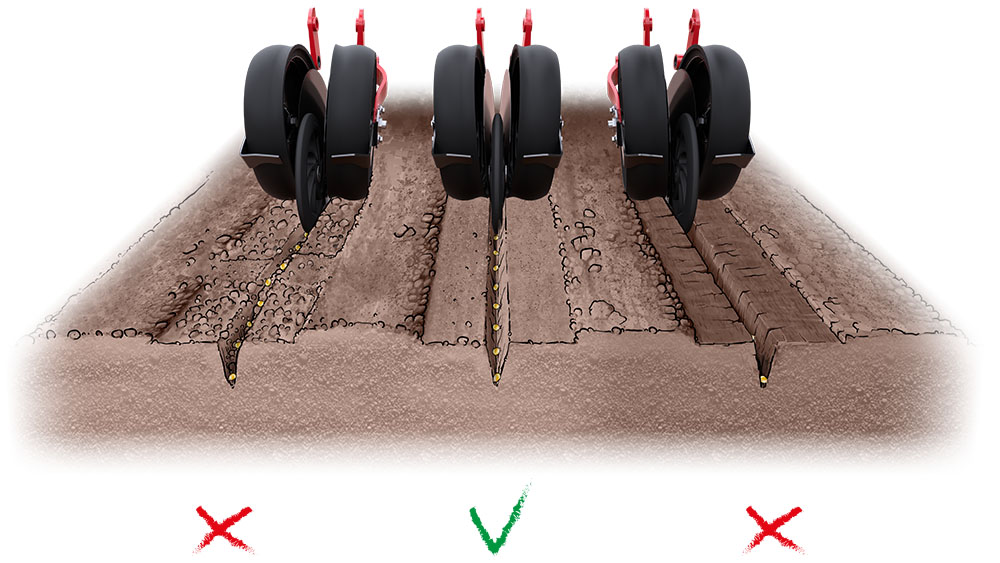

Active hydraulic downforce enables furrow management

With the active hydraulic downforce system, Tempo instantly reacts to changes in soil conditions, always maintaining the set optimum row unit pressure.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Auto singulation monitors and optimizes

With automatic motors on each row unit, seed singulation is continuously monitored and optimized. This saves time and increases the productive time in the field.

Full control at your fingertips

The iPad-based control system, Väderstad E-Control, wirelessly delivers data about each seed that travels through the planter, including seeding quality, skips, doubles, spacing and rate.

You benefit from user-friendly remote setup and calibration, as well as easy, real-time monitoring and control.

Through the iPad, you can download the most recent software updates, allowing your system to always stay current with future developments.

Farmers' experiences with Tempo K 24

Curious about what farmers think of Tempo K 24? Watch this short video testimonial and learn about the Tempo K straight from a farmer.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Tempo K: Unmatched precision at high speed

Every component on the Tempo planter is built to ensure the exact same start for all seeds. Watch this short video for some of the highlights of Tempo K.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Gallery

Technical data

| Number of rows | 24 |

| Row spacing, inch (mm) | 30 (762) |

| Working width, ft (m) | 60 (18.29) |

| Transport width, ft (m) | 15' 10" (4.6) |

| Transport height, ft (m) | 12' 6" (3,8) |

| Transport length, ft (m) | 38' (11.58) |

| Weight max, lb (kg) | 43000 (19504) |

| Weight transfer | Hyd |

| Volume seed bin, bu (l) | 150 (2x75) / 5286 (2x2643) |

| Volume fertilizer bin, gal (l) | 1500 (2x750) / 5678 (2x2839) |

| Hydraulic requirements | 4 DA + 2 FR* + LS |

| Oil flow requirements, GPM (l/min) | 55 (208) |

| Draugh requirements (hp) | 370-450 |

*One return line (case drain) without back pressure (max 2.5 bar) for draining of fan motors.

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic | N/A = Not available |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.