Wil-Rich QX2

22-60 ft

5 in

7 in

>155 hp

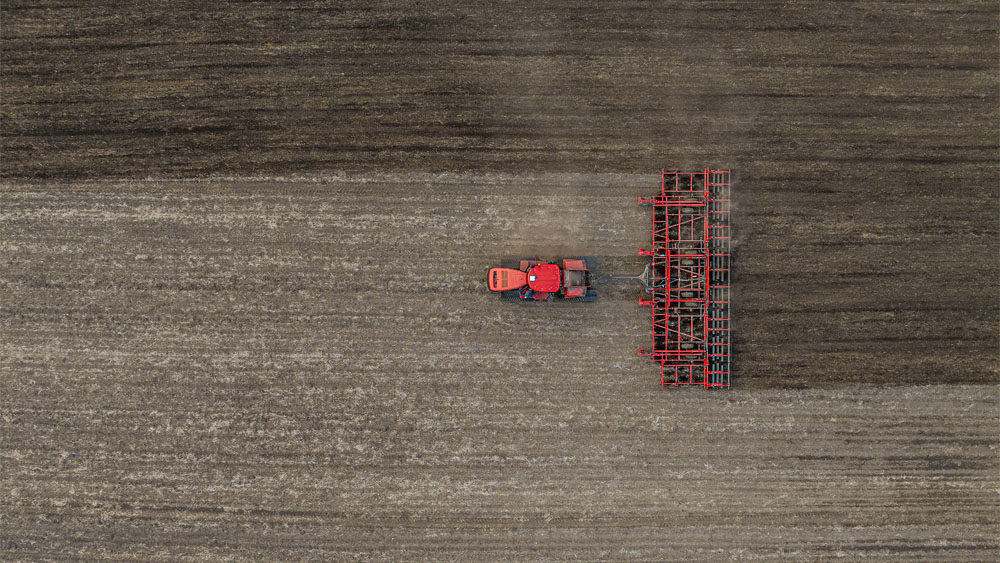

The ultimate finisher on uneven terrain

The Wil-Rich QX2 field cultivator stands out as the industry standard in secondary tillage, providing an exceptional finishing touch before high-speed planting. Designed for the most challenging field conditions, the QX2’s floating hitch delivers precise depth control on uneven terrain, promoting excellent germination and higher yields.

Mechanical weed control

The Wil-Rich QX2 provides thorough tillage, making it an effective tool for mechanically removing weeds and reducing dependency on herbicides.

Optimal seedbed preparation

The Wil-Rich QX2 sets the stage for high yields by creating an optimal seedbed, which is critical to planter performance and even emergence.

Fertilizer and herbicide incorporation

Some herbicides and fertilizers must be incorporated at consistent depths to be most effective. The Wil-Rich QX2 design provides thorough mixing and precise depth keeping for best results.

Excellent agronomic performance

A secondary tillage pass can be critical to achieving a leveled surface, smooth running of the sowing unit, and maximum effect of soil herbicides. It also helps in setting a consistent seedbed for even emergence. Give your crop the best chance to succeed while reducing risks with the Wil-Rich QX2 field cultivator.

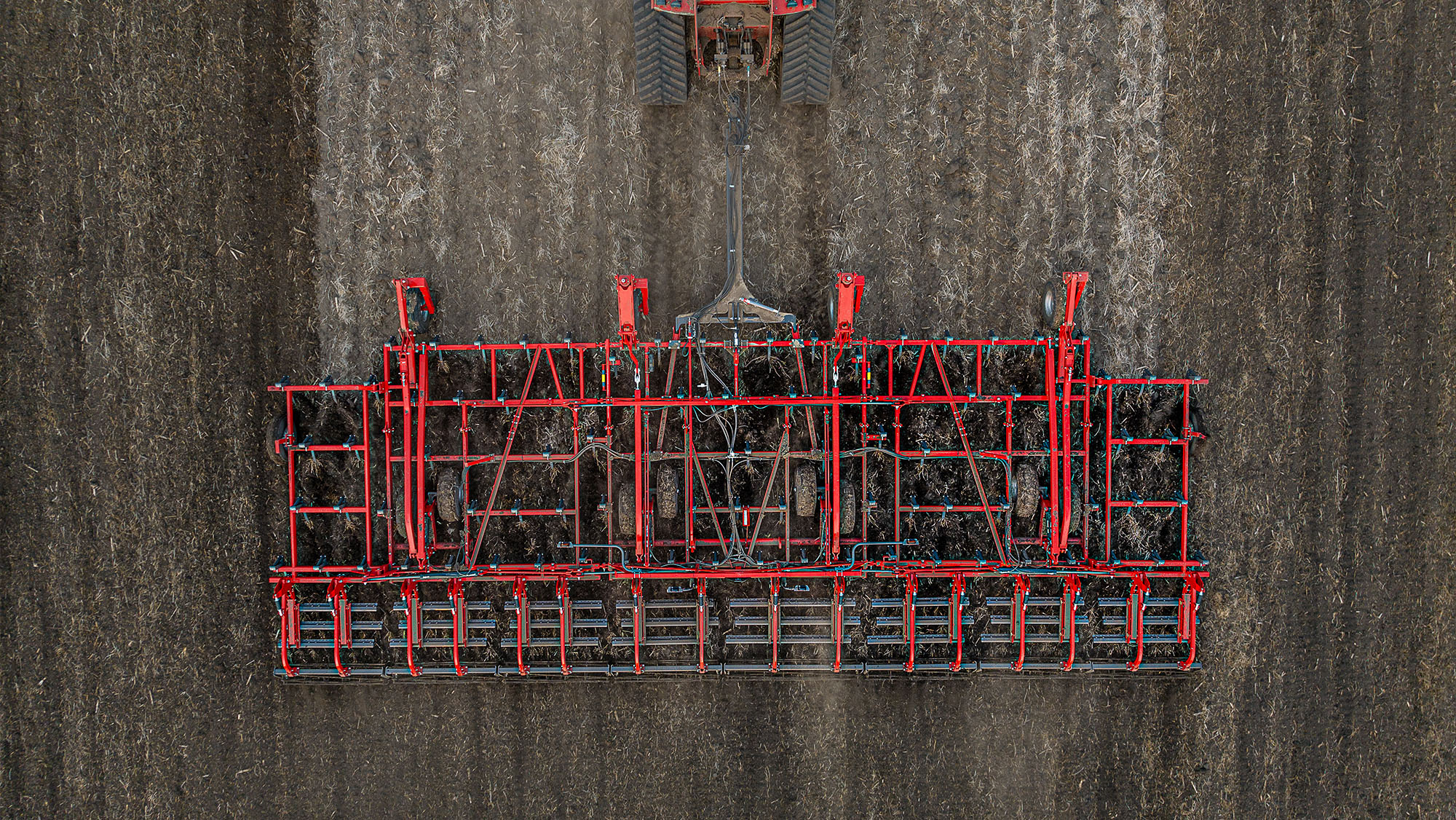

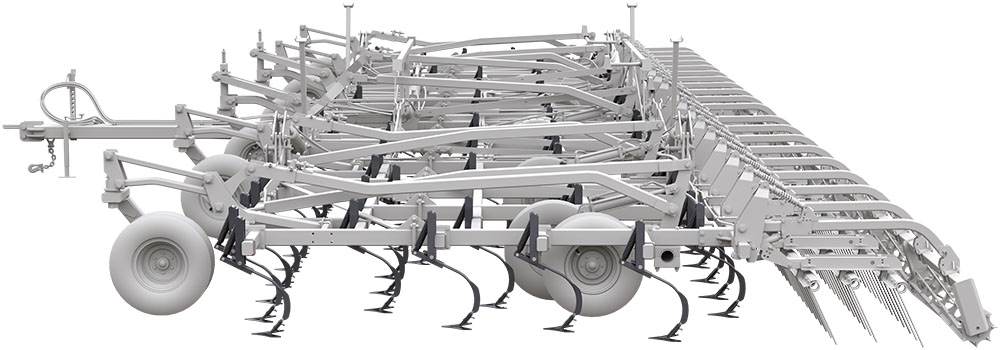

Thorough tillage performance without plugging

To achieve consistent results with a field cultivator, no strip of soil should be left untouched. However, if the shanks are spaced too closely together, the cultivator can plug up or create windrows of residue. That’s why Wil-Rich engineered a split-the-middle shank pattern on the field cultivator. Shanks on each rank work in the middle of the untilled area left by the preceding shanks. This ensures consistent tillage across the width of the implement without plugging or windrowing issues.

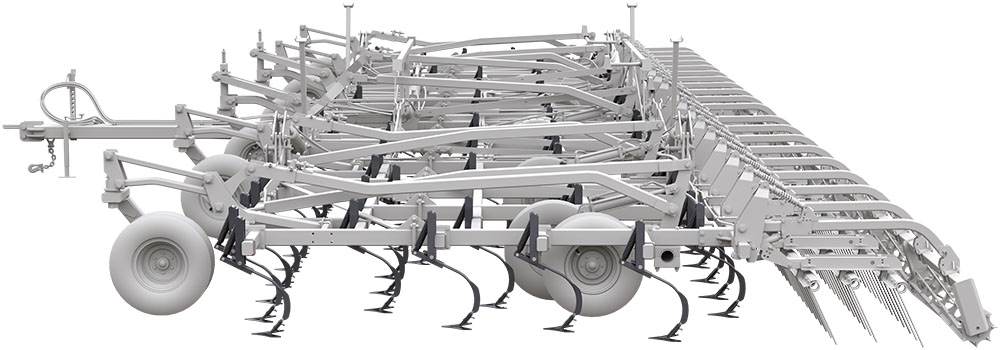

Single spring shanks for finer tillage

A single-spring shank is ideal for finer tillage performance. It provides excellent ground following capabilities with 150 lbs of trip pressure.

Double spring for tougher conditions

The double-spring option is a better choice for tougher ground conditions. It offers a downforce of 300 lbs.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

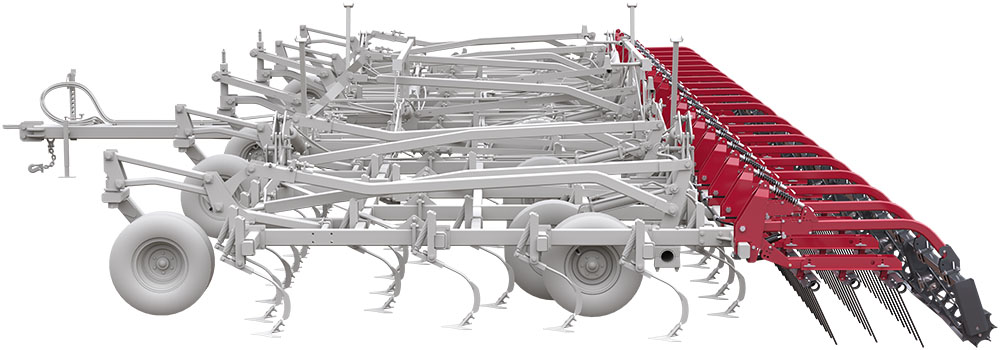

Multi-section design provides superior ground following

The Wil-Rich QX2 field cultivator is engineered with three or five sections that closely follow ground contours, even on wider models. This flexibility helps maintain consistent tillage depth in all conditions. It’s the go-to solution for farmers seeking exceptional performance in secondary tillage and preparation for high-speed planting. Designed for strength and versatility, the QX2 offers precise depth control with its floating hitch, making it ideal for uneven terrain.

Choose between two hitch designs

The Wil-Rich QX2 field cultivator comes with a floating A-frame hitch as standard, but you can opt for a floating T-frame hitch for enhanced maneuverability. The Wil-Rich QX2 has been meticulously engineered with lighter frames, allowing earlier access to your fields, even in challenging wet conditions.

A-hitch

The reliable A-hitch is the standard hitch style on the Wil-Rich QX2. It includes a weight transfer kit, which shifts weight onto the hitch to improve towing stability.

T-hitch for a tighter turning radius

The T-hitch option allows for a tighter turning radius, since the narrower profile provides extra clearance between the hitch and rear tractor wheels. Like the A-hitch, it has a weight transfer kit that shifts weight onto the hitch for improved towing stability.

The T-hitch is exclusively offered for five-section models featuring a 13 ft mainframe.

A closer look at the Wil-Rich QX2

Gauge wheels engineered for better performance

An open design of the caster gauge wheels on the Wil-Rich QX2 helps prevent them from negatively affecting tillage performance. As a result, operators experience minimized plugging with greater stability both in the field and on the road. Additionally, they offer easy maintenance, so more time can be spent in the field.

Quick, easy adjustments

Need to adjust the tillage depth on the fly? Single-point depth control allows operators to adjust the working depth for the entire implement from a single location, instead of having to make manual adjustments at each gauge wheel. This feature can significantly reduce the time spent on adjusting tillage depth. Furthermore, it increases the likelihood that operators will make the necessary adjustments to attain the desired tillage outcomes.

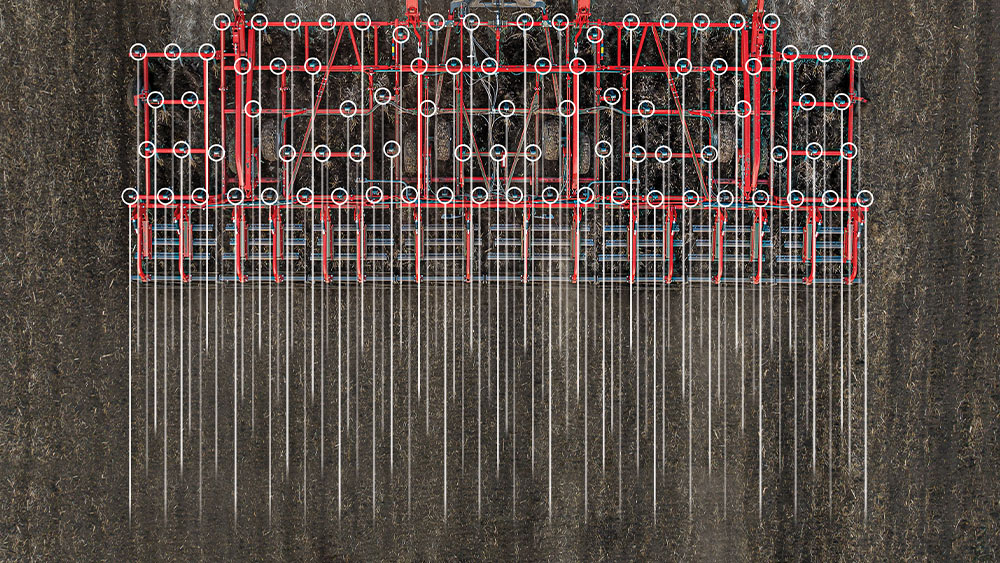

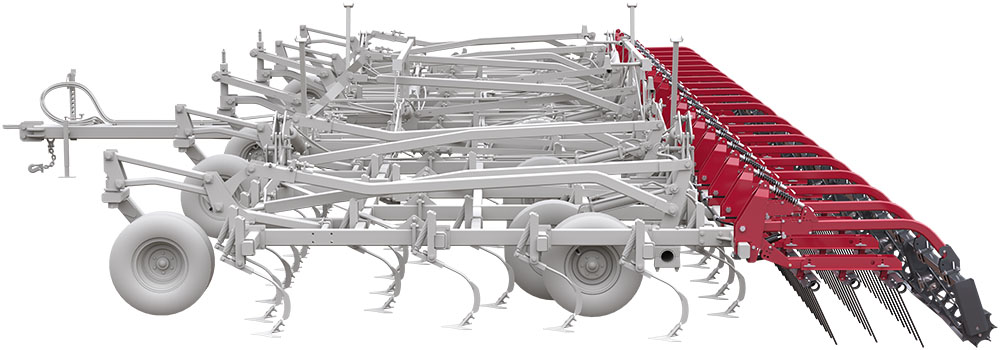

Creating the ideal seedbed

Four finishing attachment options are available to accommodate a variety of field conditions and personal preferences. Each option offers unique benefits in helping create the ideal seedbed.

- 3-bar coil tine harrow w/ rolling basket (round bar)

- 3-bar coil tine harrow w/ rolling basket (flat bar)

- 4-bar coil tine harrow

- 5-bar spike tooth harrow

Consistent depth in uneven ground

The Wil-Rich QX2 is designed to maintain consistent tillage depth, despite fluctuations in the ground contour. This is made possible through the floating hitch, which pivots freely at the implement to help the field cultivator follow uneven terrain. Two floating hitch styles are available on the QX2 to meet the needs of different farming operations: an A-hitch and a T-hitch.

Choose Wil-Rich XL2 for level terrain

The main difference between the QX2 and XL2 models is the hitch type. XL2 models are equipped with the field-proven, time-tested level lift hitch, which allows weight transfer to the tractor. Designed for level field conditions, this hitch type creates a planter-ready seedbed.

Product concept

Zone 1 – Mixing

The five ranks of shanks offer an effective spacing of 7 in. This configuration results in consistent tillage across the width of the machine for incorporating fertilizer or herbicides, removing weeds, preparing a seedbed, or all of the above.

Zone 2 – Levelling

Finishing attachments level the soil profile and create a planter-ready seedbed. Four types of attachments are available to meet the needs of various operations and soil conditions.

Gallery

Technical data

| 13QX² 32 | 13QX² 32-34 | 13QX² 32-42 | 13QX² 32-45 | 13QX² 37 | |

| Number of shanks | 55 | 59 | 73 | 77 | 63 |

| Cutting width, ft | 32.1 | 34.4 | 42.6 | 44.9 | 36.75 |

| Inner wing, ft | 9.3 | 9.3 | 9.3 | 9.3 | 11.7 |

| Outer wing, ft | - | - | 5 | 6 | - |

| Number of tires | 12 | 12 | 14 | 14 | 12 |

| Transport width, ft | 18.4 | 18.4 | 18.4 | 18.4 | 18.4 |

| Transport height, ft | 12.75 | 13.8 | 13.4 | 13.4 | 14.9 |

| Weight*, lbs | 13,500 | 13,700 | 16,300 | 16,500 | 14,300 |

| Horsepower requirement | 225-290 | 235-300 | 245-375 | 315-405 | 260-335 |

| 13QX² 37-42 | 13QX² 37-50 | 13QX² 46-50 | 13QX² 55 | 13QX² 55-60 | |

| Number of shanks | 73 | 85 | 87 | 95 | 103 |

| Cutting width, ft | 42.6 | 49.6 | 50.75 | 55.4 | 60.1 |

| Inner wing, ft | 11.7 | 11.7 | 9.3 | 11.7 | 11.7 |

| Outer wing, ft | - | 6 | 7 | 9.3 | 9.3 |

| Number of tires | 12 | 14 | 18 | 18 | 18 |

| Transport width, ft | 18.4 | 18.4 | 18.4 | 18.4 | 18.4 |

| Transport height, ft | 15.5 | 15.5 | 13.5 | 15.5 | 15.5 |

| Weight*, lbs | 16,500 | 17,300 | 20,500 | 21,600 | 22,000 |

| Horsepower requirement | 295-375 | 350-450 | 350-450 | 385-495 | 425-540 |

*Approx weight: base weight + (number of shanks x shank weight).

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.