Tempo L 8-32 Central Fill

8-24

450-800mm

>150hp

3000/7200 litre

Capacity and precision maximised

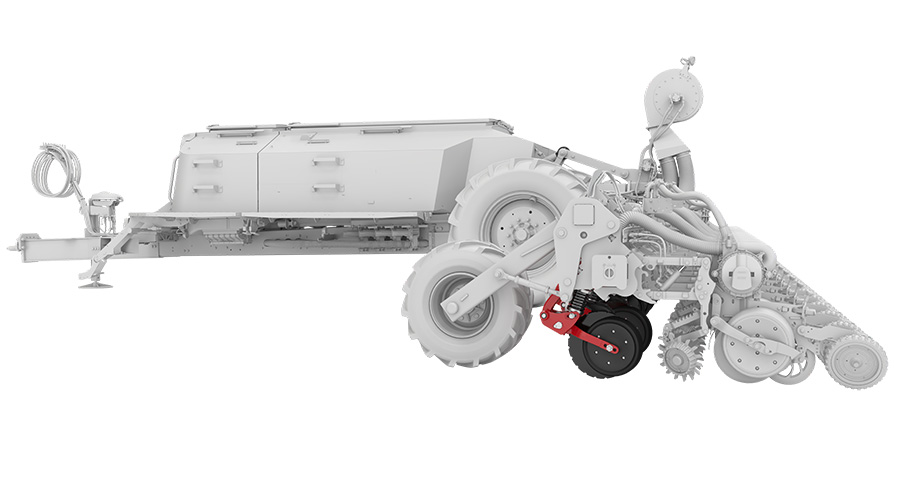

Tempo L Central Fill is available with 8, 10, 12, 16, 18, 24 or 32 row units. It is equipped with a high-capacity central seed hopper, sending out seeds to the row units. Tempo L Central Fill delivers unmatched planting capacity and precision. Additionally, it manages a full range of seeds - from small seeds like oilseed rape, to maize and high rates of soya.

Väderstad Tempo is a new generation high-speed planter, delivering an unmatched precision at double the speed of traditional planters. No-till, min-till or conventional tillage – Tempo performs exceptionally in all conditions. The crops gets the best start possible which results in an even emergence.

High-precision seed metering

The technology behind the new Väderstad Tempo Central Seed Fill system is very intuitive. There is no central motor metering out seeds - instead each row unit regulates the number of seeds needed to assist its individual high-precision PowerShoot seed metering system.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

High capacity hopper

Underneath the central 3 000 litre seed hopper, there is a feeding system for the row units. If there is an airstream in one particular gate, that gate will pick up seeds and send it out to the row unit. Every gate supports two row units thru a divider on the wings.

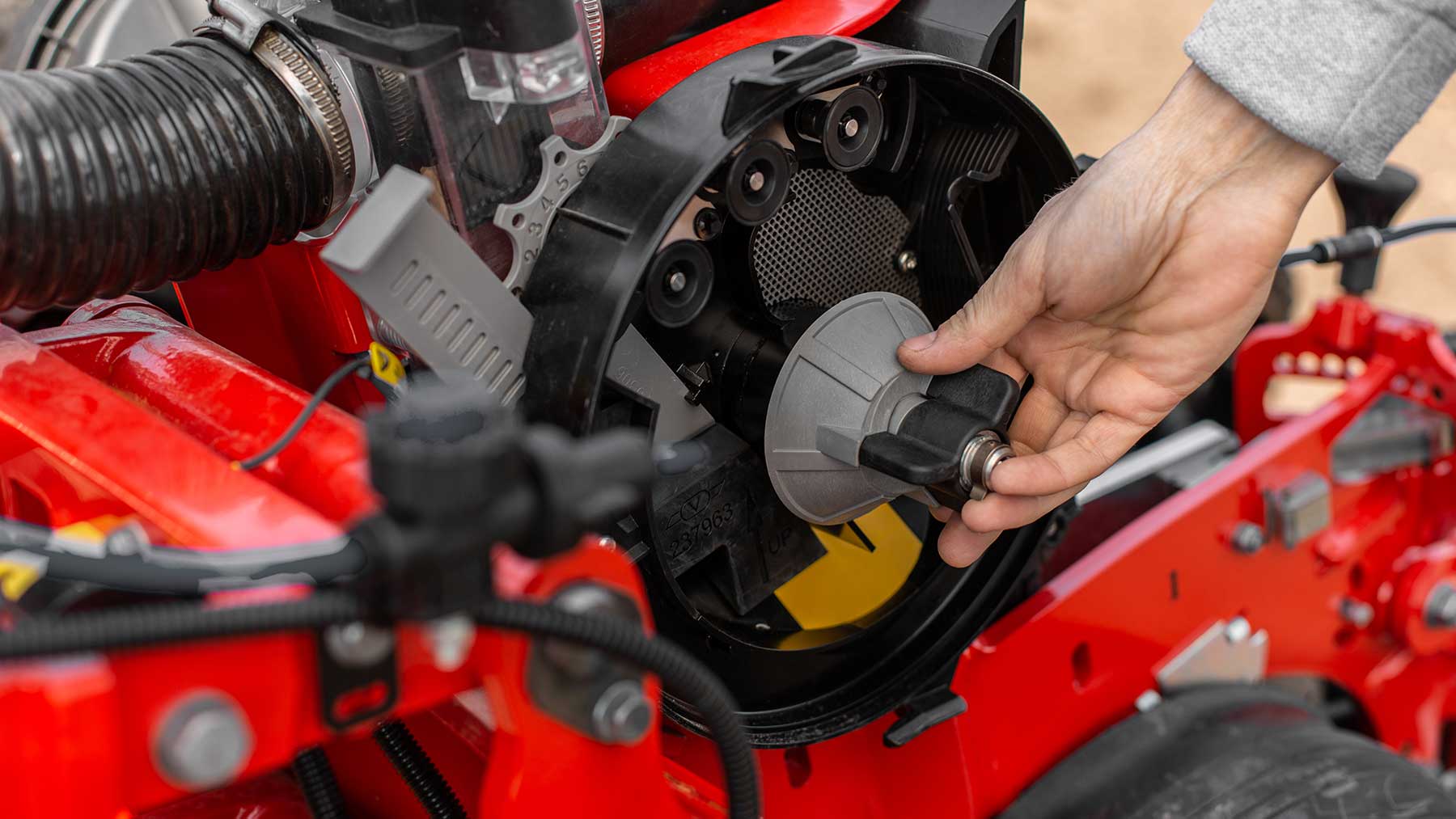

Seed collector

On each row unit there is a collector on top of the PowerShoot seed metering system. The collector works as a small buffer of seeds. When the collector is full of seeds the airstream in the feeding system stops, meaning that the transport of seed stops for that row unit.

Calling for seeds

When the seed level in the collector starts to run low, the airstream starts again making the Central Seed Fill system transport seeds to fill up the collector. This means that each row unit will call for seeds, when needed, by themselves.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

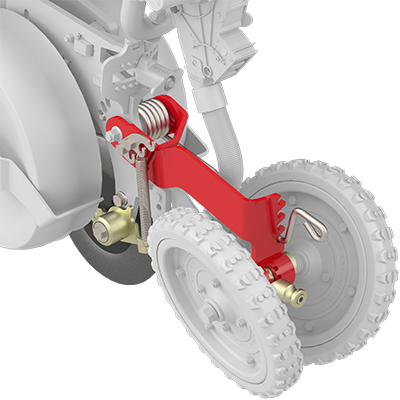

Telescopic wheel axle

To ensure the transport wheels follow the row spacing, Tempo L is fitted with a telescopic wheel axle which can be easily adjusted from the cab. So whatever the row spacing, the transport wheels can be adjusted to always run between the seed rows. The wheel axles are easily set to 3m width for transport.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

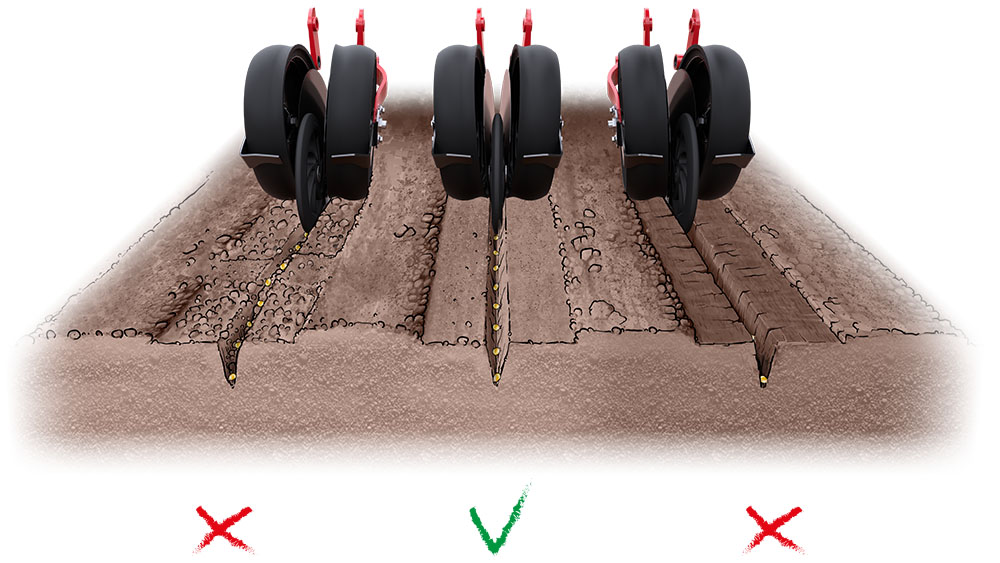

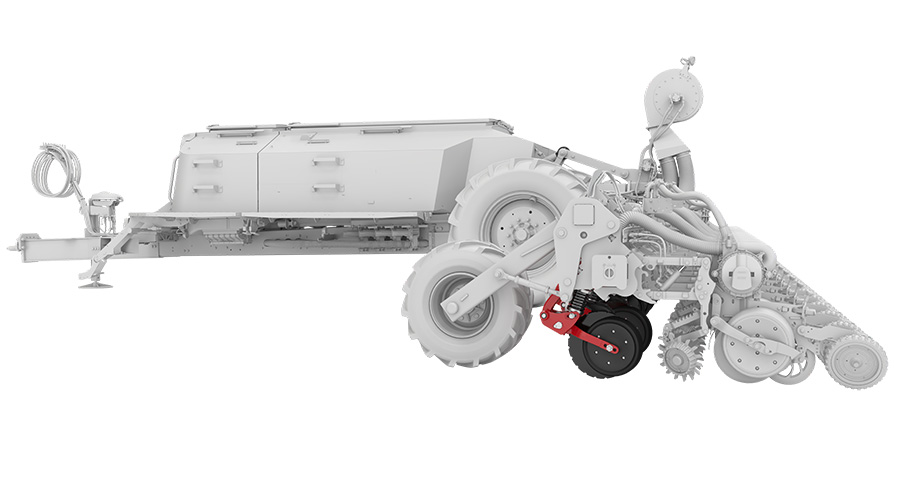

Perfect depth control

Tempo L is equipped with hydraulic wing pressure which transfers weight from the inner section of the machine to its outer wings.

This enables Tempo L to respond to any irregularities on the field and ensure an even emergence.

Optimised accuracy with next-level automation

By upgrading the data processing capabilities of the planter, additional features to ensure accuracy in the field are unlocked. The optional features are curve compensation, active hydraulic downforce and auto singulation.

Curve compensation ensures a consistent rate

Active sensors communicate when the machine is turning and adjust each row unit's metering output to ensure a consistent rate over the full Tempo planter width.

Active hydraulic downforce enables furrow management

With the active hydraulic downforce system, Tempo instantly reacts to changes in soil conditions, always maintaining the set optimum row unit pressure.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Auto singulation monitors and optimises

With automatic motors on each row unit, seed singulation is continuously monitored and optimised. This saves time and increases productive time in the field.

Full control at your fingertips

The iPad-based control system, Väderstad E-Control wirelessly delivers data about each seed that travels through the machine, including seeding quality, skips, doubles, distance in the row, and rate.

You benefit from user-friendly remote set up and calibration, as well as easy, real-time monitoring and control.

With the iPad you can upload the most recent program software which allows you to benefit from future developments.

QuickStart

See our QuickStart movies for your Tempo L.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

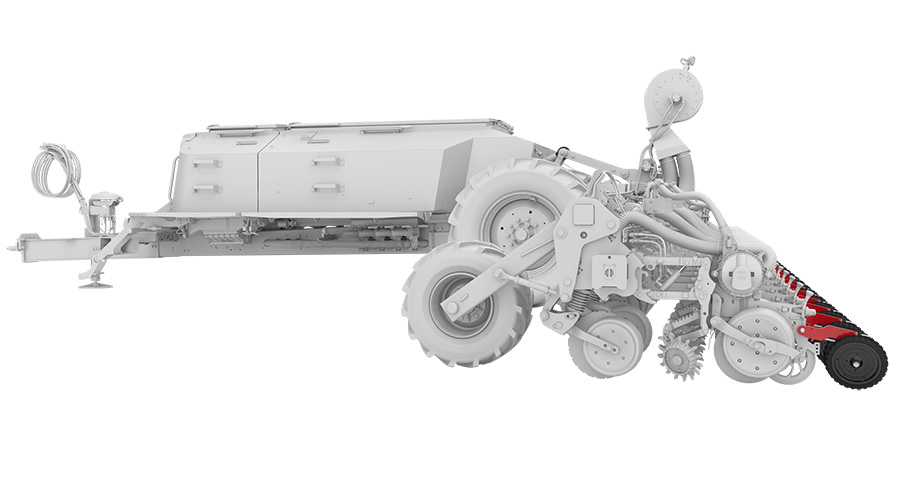

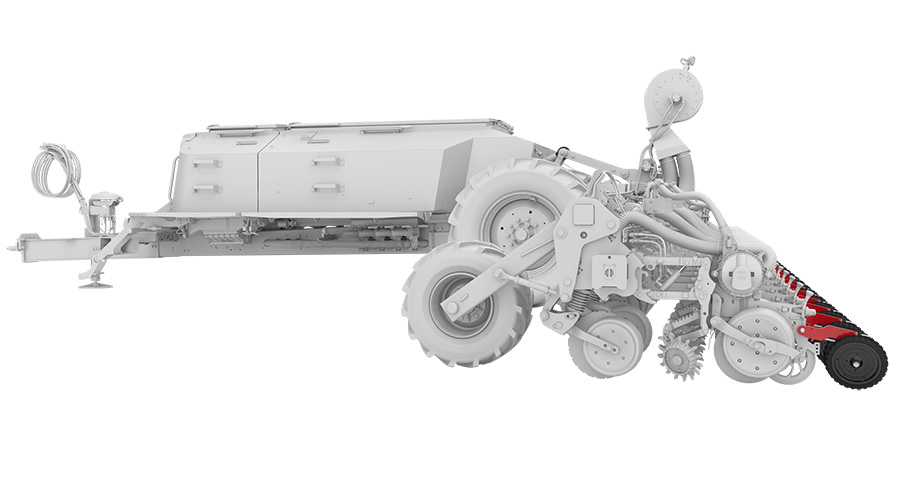

Zone 1 - Fertiliser placement (option)

To fit different farming needs, Tempo L with Central Fill, is available with or without fertiliser output. The seed-only models are equipped with a central 3 000 litre hopper for seeds, while the seed and fertiliser models utilize a 7 200 litre hopper with two compartments: 2 200 litres for seed, and 5 000 litres for fertiliser.

The electric driven Fenix III has the capability to adapt the fertiliser rate to varying field conditions by using a variable rate system. The high capacity fertiliser coulters maintains the high precision even at high speed.

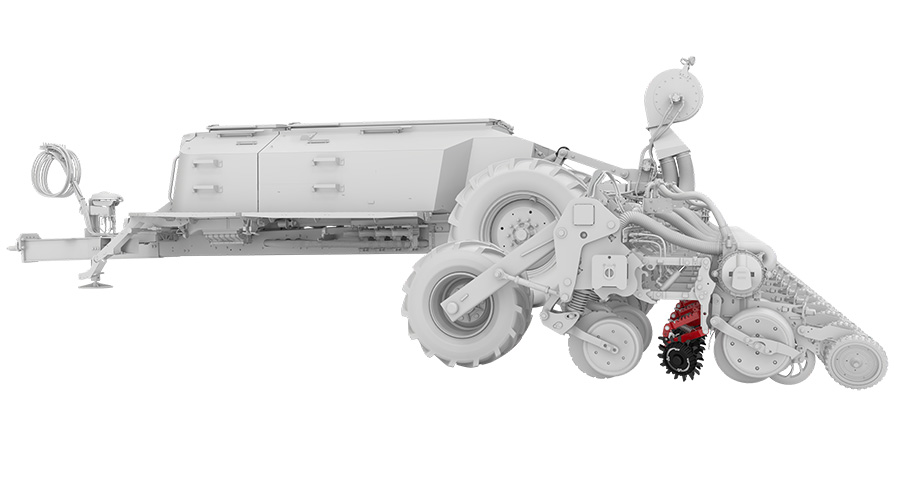

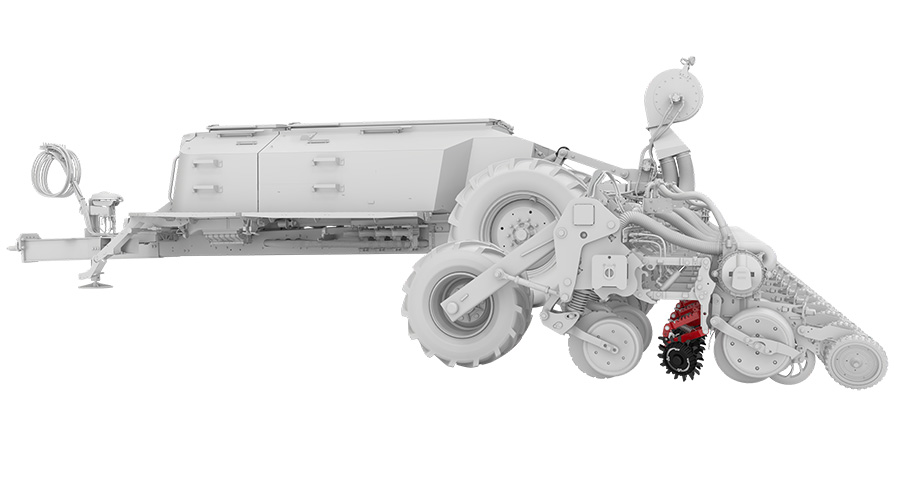

Zone 2 - Row cleaners (option)

The row cleaners are an option on Tempo. The task of the row cleaners is to remove crop residues, clods and stones. The demand for row cleaners is much higher when planting into no-till or when planting into fields with large amount of residues.

Zone 3 - Seed placement

With Tempo, planting can be carried out at very high speed, without compromising exceptional precision and accuracy. Tempo is extremely accurate and the seed meter assures perfect placement for every seed. This precision is of greatest importance to maximise the yield.

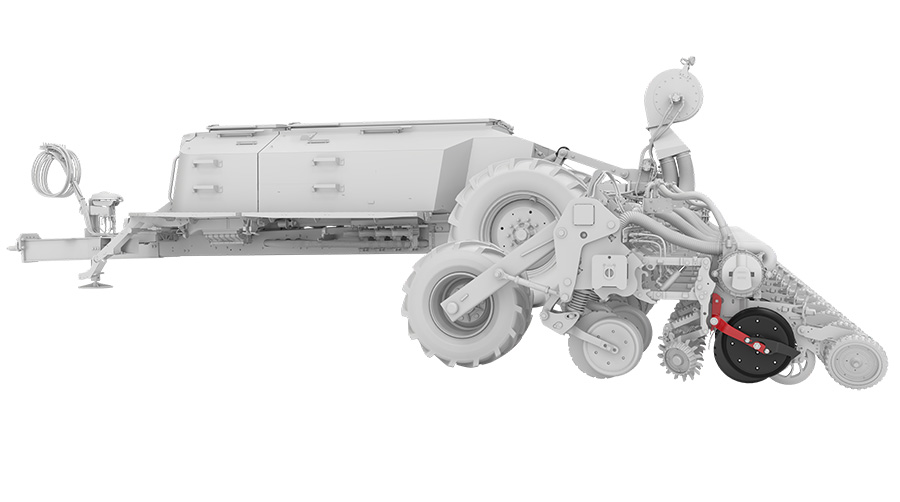

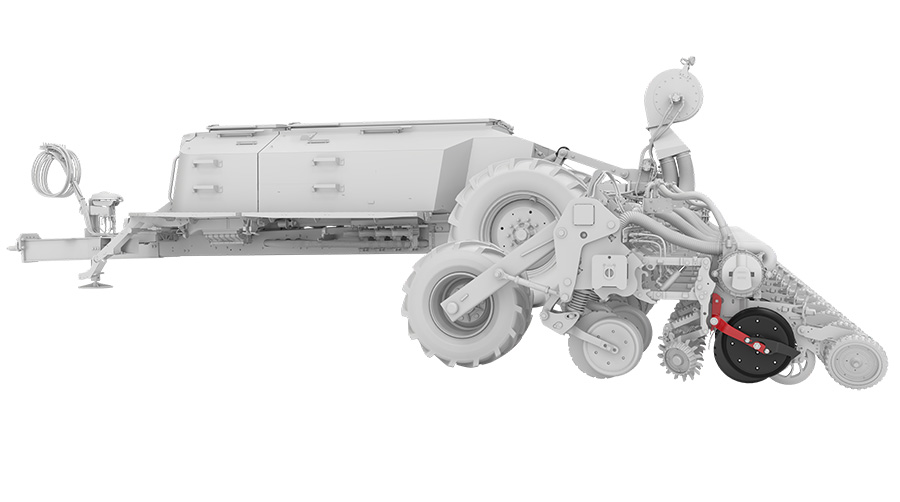

Zone 4 - Closing

When the seed is planted the closing wheel closes the seed slot and ensures perfect conditions for germination. Depending on farming requirements, the interface further allows for several industry-standard third-party closing wheel solutions.

Gallery

Technical data

| Number of rows | 8 | 10 | 12 | 16 | 18 | 24 | 32 |

| Row spacing (mm) | 700/750/762/800 | 750 | 450/457/500/508/ | 700/750/762 | 450/457/500/508 | 450/457/500/508/559 | 375/381 |

| 559/700/750/762/800 | |||||||

| Frame width | 6.1 | 7.2 | 6,1-9,6 | 10,8-12,0 | 8,3-9,8 | 10,8-12,0 | 12.1 |

| Working width (m) | 5,6-6,4 | 7.5 | 8,4-9,6 | 11,2-12,2 | 8,1-9,1 | 10,8-12,2 | 12,0-12,2 |

| Transport width (m) | 3 | 3,0-3,4*** | 3 | 3,0-3,4*** | 3,0-3,4*** | 3,0-3,4*** | 3.85 |

| Transport height (m) | 4 | 4 | 4 | 4 | 4 | 4 | 4.25 |

| Weight Seed only version (kg)* | 6100-6900 | 6400-7200 | 6700-7700 | 7500-8600 | 7500-8800 | 8600-9800 | 11000-12800 |

| Weight Combi version (kg)* | N/A | N/A | N/A | 11500 -12100 | N/A | 13800-14300 | N/A |

| Weight transfer | Mech-/Hyd | Mech-/Hyd | Mech-/Hyd | Hyd | Hyd | Hyd | Hyd |

| Volume seed hopper (l) | 3000 | 3000 | 3000 | 2200/3000 | 3000 | 2200/3000 | 3000 |

| Volume fertiliser hopper (l) | N/A | N/A | N/A | 5000 | N/A | 5000 | N/A |

| Hydraulic requirements (Seed only) | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** |

| Hydraulic requirements (Combi) | N/A | N/A | N/A | 6 DA + 2 FR** | N/A | 6 DA + 2 FR** | N/A |

| Oil flow requirements (l/min) | 110-130 | 110-130 | 110-200 | 140-230 | 140-200 | 140-260 | 140-200 |

| Draught requirements from (hp) | 150-200 | 180-230 | 200-300 | 300-350 | 300-350 | 300-350 | 350-400 |

*Weight min-max depends on equipment. Empty hoppers.

**One return line (case drain) without back pressure (max 2.5 bar) for draining of fan motors.

***3.4m transport width with dual wheels.